CAPABILITIES

BIZ continues to invest in the latest engineering technology to ensure the highest quality and widest specification of product are available to our customers. Our company processes are structured to provide quality and traceability. We manage projects from initial design concept right through to manufacture of prototypes, batch or high-volume quantities. BIZ can also combine various subcontract supply chains to reduce the burden on our clients having to liaise with multiple companies.

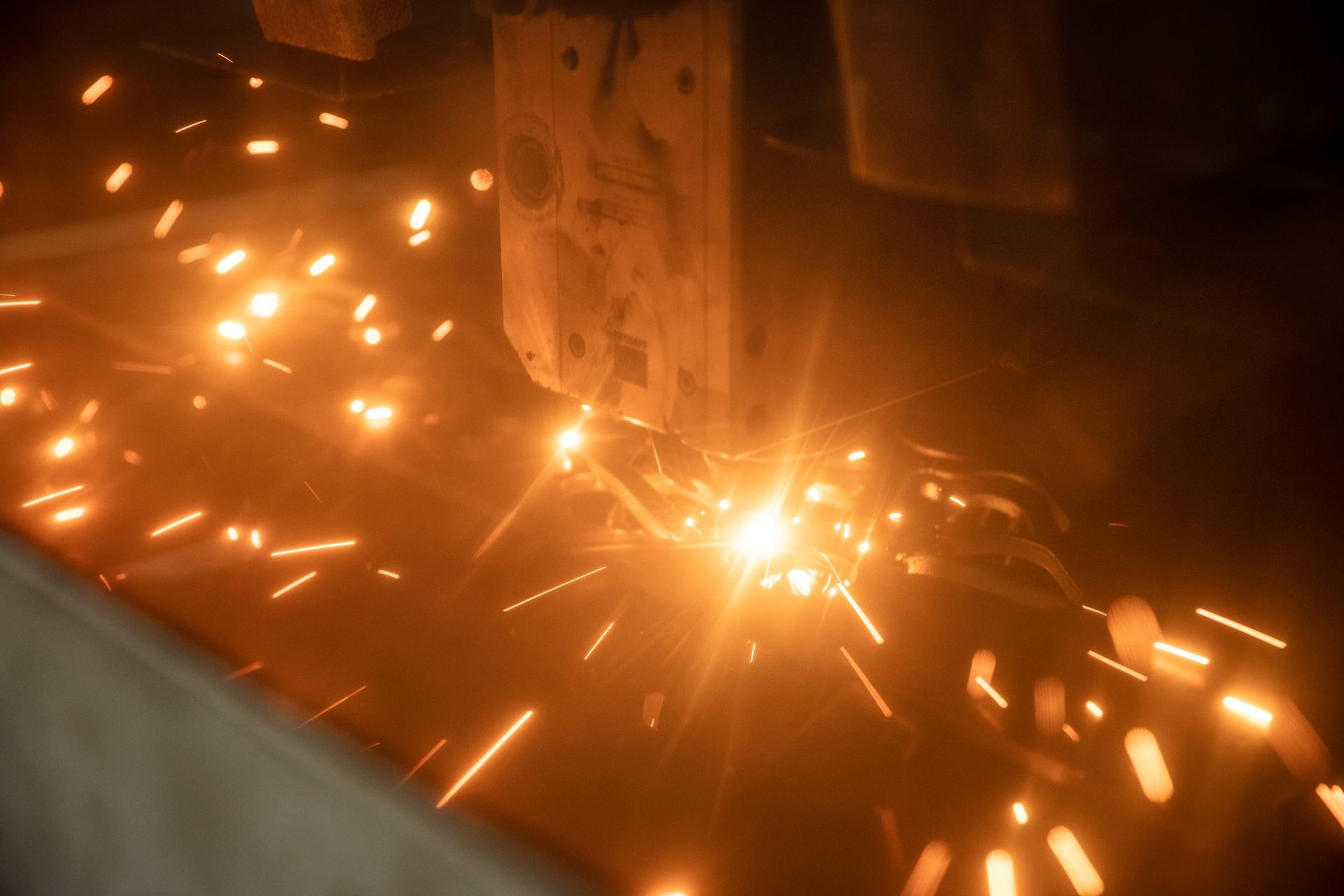

CNC LASER CUTTING

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

We operate three flatbed laser cutting machines with automatic pallet changers. These machines will comfortably cut up to 20mm mild steel, 12mm stainless steel, 10mm aluminium and 6mm copper & brass. The laser cutting process leaves no burrs or cutting residue therefore leaving the parts safe to handle. We also have our own nitrogen generating plant on site. By generating nitrogen in-house we can reduce our operating costs and pass these savings on to our customers. We offer laser cutting as part of a general fabrication package and also as a standalone cutting service.

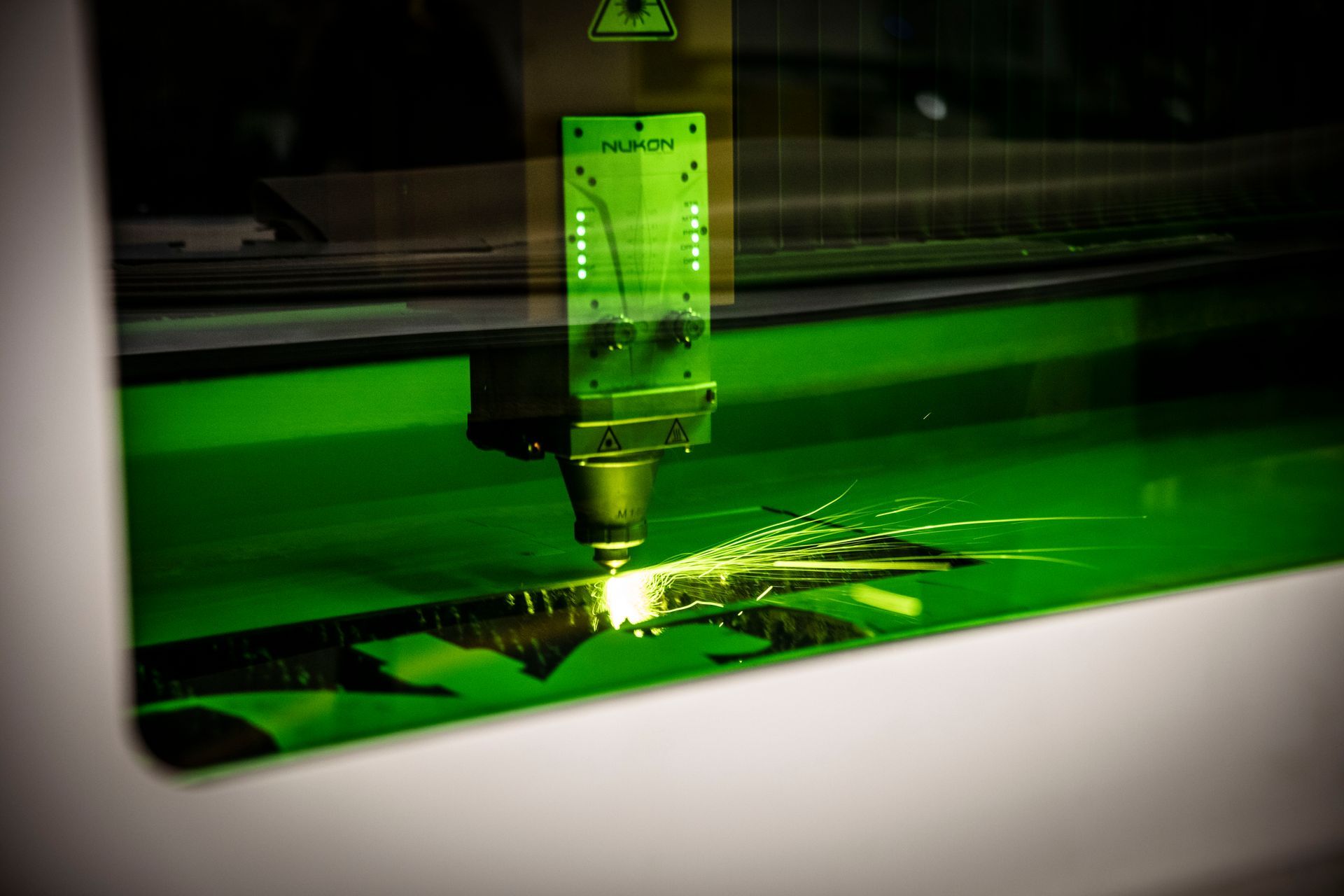

TUBE LASER

The tube laser is a cutting-edge tool with impressive capabilities. It can cut tubing with diameters up to 200mm and wall thicknesses up to 8mm, handling materials like stainless steel, aluminium, mild steel, copper, and brass. This machine is suitable for both one-off projects and batch quantities. Beyond tubes, it can cut various shapes, including circular, box, flat, channel, and irregular forms. The tube laser is known for its speed, flexibility, accuracy, and cost-effectiveness, making it a crucial asset in modern metal fabrication for a wide range of applications.